I'm Easy Tiger... Grrr! Well, maybe not this time!

16/2/15 - Day 1

In my pile of 1/72 plastic kits I have three Tiger Is: an Early-Production model by Zvezda; a Mid-Production version by Trumpeter; and a Late-Production vehicle by Dragon, the latter with integral Zimmerit and a rather cool set of Tiger Aces figures. I've decided I'd like to build them in chronological order, so I've started on the Zvezda first.

18/2/15 - Day 3

I really enjoyed building Zvezda's 'snap-fit' 1/72 Panther a while back. I've now embarked upon my second Zvezda 1-72 kit. Strictly speaking this is my third kit by this Russian manufacturer, my second being a 1/100 half-track, built on the very day of Yule (as a kind of stocking-filler treat). This second 'proper' and larger model from Russia's 'Star' brand comes in the shape of their Early Production Tiger.

What's In the Box:

What's In the Box:

The Panther kit was a real beauty in terms of design and build, crisply cast and fitting together like a dream. And so cleverly designed, in that it really was an 100% snap-fit kit. This said, I did glue mine together. And, no fault of the kit, I screwed up with the turret base-plate, resulting in a turret that didn't quite sit flat on the hull. Still, it'll make a usable vehicle nevertheless, methinks.

Having built several more kits in the interim, some of which were considerably more challenging - ranging from the high part count and fiddly three-in-one nature of Revell's Sdkfz 7/1 with Flak 38, to an Ace RSO (also with flak, as it happens) with labour intensive photo-etched tracks and some very poorly cast and ill-fitting components - I felt that this kit, with a relatively low part count, shouldn't be too difficult. I was kind of expecting something like the experience I had fairly recently building Trumpeter's JagdTiger.

The rear hull plate assembled.

This is all the lovely rendered detail that you won't be

able to see when this piece is in position!

A view of the rear hull in place.

A view of the front hull in place, inc.

that lovely detailed track-section.

17/2/15 - Day 2

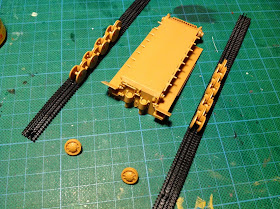

The first stage of my work on this kit was steps one and two, completed yesterday. These steps involved constructing a certain amount of the hull, and met the expectations of an easy and satisfying build mentioned above. But then came the running gear and tracks. Often a tricky part of a 1/72 armour build, I expected this to be, relatively speaking, a breeze. After all, Zvezda make it simpler than many of their competitors, by supplying large elements of the running gear as multiple wheel blocks.

Here you can see two of the road wheel blocks prior to assembly.

This is a great idea in principle, as getting all the road wheels properly aligned is often a real challenge. Usually I do a pretty rubbish job! Having just read how Alex Clark uses Lego sometimes, to make a species of support for this fiddly stage of proceedings, I feel I must try that! I read about this in a book a friend has - Modelling Small Scale Armour - that I decided to buy off Amazon's Kindle service a few days back. As a lover of real books, this is my first eBook purchase (altho' I already have quite a few digital freebies).

Alex Clark's handy book (available here). Also my first ever Kindle eBook purchase!

Pacing oneself is important too. Sometimes one needs to know when to stop. I crossed a line on this, day two of my build, and it really cost me! Succumbing to the desire to move the model along briskly, a wish motivated in part by the fact I'm only getting to snatch occasional moments to do my modelling, and using glue on a kit that proudly proclaims you don't need to, I wound up busting one whole set of track and road wheels.

One of the only two pics I remembered to take during the 'meltdown' phase of this models construction! Here you can see the sheared surface of the hull-mounted suspension units and the wheel-axles.

Basically the glue that mounted one long run of wheels, which as a solvent melts the two glued surfaces somewhat, weakened this crucial structural part of the model. When, shortly afterwards, I was applying downward pressure to the tracks, to click the last two parts in to place, I ended up shearing the whole block away from the chassis. I should have left the road wheels to cement hard in place before attempting to finish linking the tracks. I suspect that if I hadn't used a solvent glue this problem may not have arisen at all.

Once this had happened I checked the other set of road-wheels and tracks. The same problem affected this set also, but to a much lesser, and therefore non-calamitous degree. Whilst a few wheels were slightly off-position, the whole set was more or less as it should be. If I was to stand any chance of saving the broken model I had to bite the bullet, and try out a new technique, 'pinning'.

My newly acquired set of Rolson Archimedean drill and micro drill-bits, bought to replace a set I'd had on long-term loan from my dad, arrived today, and served me well in this task. The pins themselves were made from a straightened paper-clip, snipped into suitably short pin-like lengths with my modelling snips.

Making the pins for 'pinning' the wheel assembly back onto the model, using paperclips for the pins.

The paper-clip metal seems to be about 1mm in diameter, so I drilled out a set of eight 1.2mm holes, four in the chassis, and four in the corresponding opposite parts of the road wheel assemblies. These both needed some cleaning up, with a scalpel and some fine grade sandpaper, as the solvent glue had left them in an ugly state after they sheared away from each other.

Originally the construction of the wheels and tracks was intended to be my little bit of modelling fun before I went to to bed. But I messed up the tracks at about 9/9.30pm, just about the time I ought to have been retiring. The rescue operation would take me through till well past midnight. One thing that really galls me - and I can't quite believe that I didn't do it - is that I didn't document this vexing but nevertheless very interesting stage of the build!

To start with I drilled out holes on the two end and the two middle suspension units that take the eight road wheels on the lower chassis which, in this Zvezda kit, are crisply pre-moulded as integral parts of the lower 'tub'. And of course I drilled the corresponding holes on the wheel block as well, through the centre of the wheel axles. This involved trying to start the holes off with a guide hole, using the tip of a scalpel. Like most of this rescue operation, this was both very fiddly and far from easy!

I then super-glued the four metal pins into their holes. These needed a bit of filing, which I did using a file from a set of 'diamond' files my friend and neighbour Denis* gave me recently, at the clipped ends, to get the male parts into their female sockets. I was worried the holes wouldn't align - I didn't bother using any of the the methods I've recently seen demonstrated online, for carefully aligning such parts, and knew I was taking a bit of a risk - but fortunately they did.

But I ballsed up yet again, initially super-gluing the whole assembly on the wrong way! I.e. upside down... Doh! During this whole episode I also sliced off the idler wheel, which was getting in the way. Altho' whether this was really necessary or not, or was only entailed by the mistaken step just alluded to, I can't recall now. This whole stage passed in a red mist of panic and stress! And I guess that's why I forgot to document it all as well. Hey-ho, so it sometimes goes!

I managed to prise off the wheels (and the still attached track, etc.), which pulled out a pin that then proved a bit of a challenge to re-seat, and eventually got the whole shebang properly mounted. Gluing the idler-wheel back into position was another headache, and involved holding the piece in place manually for about 10-15 minutes, as the attached track was shifting it out of position. What a palaver!

The 'good' side. Actually now the bad side!

Rather amazingly, this botched side of the model is now the better mounted part! Close examination underneath shows that there are places where the parts that aren't pinned don't quite meet, but these won't be visible without picking the kit up and scrutinising it closely underneath.

The bad or pinned side. Now also the better aligned side!

Indeed, in the accompanying photos, taken to illustrate this problem - by this stage the panic was subsiding, and I remembered to take some pics! - it's pretty hard to see. And, who knows, I may even be able to fill these gaps in at a later stage? The pinning has both strengthened these attachments, and left them properly aligned to the chassis, whereas the side where I didn't actually break the assembly completely is slightly misaligned, due to the weakening of the joints through use of the solvent glue.

Even zooming in here it's hard to see that the pinned set isn't perfectly fitted!

My oh my, but you do live and learn as a model maker, and no mistake! At least, I do hope I am actually learning from this catalogue of errors? I have to confess that I almost feel tempted to break off the 'good' side, and pin that as well. For several reasons: 1) to get it better aligned, 2) to strengthen it, and 3) so as to document the process with photos. That last omission really irks me, as I certainly don't want to put myself through this whole process unnecessarily again!

-----

18/2/15 - Day 3

I remembered to spray the inner hull. If you don't there's the danger you'll be

able to see (in this instance) beige plastic through the engine deck grills.

In my morning model-making session today I completed stage seven of this ten-step build. This mainly consisted of attaching detail to the upper superstructure of the hull. A couple more good things about these Zvezda kits are worth noting here:

Firstly, the snap-fit assembly means that if you're choosing to glue the parts anyway, as I do, you can do so from the rear of a major part, so that today, for example, most of the stuff I glued to the upper hull had the glue applied to the inner surface of the hull, where the pegs go through the holes in the top. This means less worries about excess glue showing on the outside of the finished model.

A second good point is that most of the stuff on the body of the tank - tools, fire-extinguisher, etc, is supplied as separate parts. Some kits give you every wheel individually, which is, I guess, part of the fun (having lots of parts to stick together!), but then they have stuff like the tools moulded to the body of the tank. This is of course less realistic, because of undercuts. I like Zvezda's way of doing things.

There are two other points I'll mention now. One is that when I was dealing with yesterday's disaster with wheels and tracks, all but one of the U-clips (for the towing cables) pinged off. I didn't notice this until after I'd done all the work pinning the broken assembly back in place. Until fairly recently I've had a good track record for not losing many such tiny parts.

But the wire handles for my Attack 1/7? Hetzer (more about this in another post soon) started a bad trend recently. I lost more of those than I finally kept and used: nine handles made; four used; five lost! I was able to find two of the U-clips in this case, so there are now three on the model. I do hope the fourth turns up! Fortunately the cables on this model are shown fixed to other parts of the body. So even if I don't find or replace the lost one, the cables will still sit where they're meant to.

The second and final thing I want to mention in this instalment is that on this occasion I've actually made sure to spray black paint inside the rear body of the tank before competing the hull. I usually only think about this once I've competed the hull, by which point I'm thinking 'uh-oh, the raw plastic of the kit is visible through those grilles!' Taking this step now is obviously to ensure that anything seen through the (nicely detailed) engine compartment grilles shows as if in dark shadow, as opposed to the original plastic colour of the model!

-----

A second sitting today has brought me to the stage of completion, construction wise. Thankfully there were no more debacles like the above episode with the running gear! I did find that quite a few holes for the more delicate parts needed opening up a little, so as not to break some of the nice little tools attached to the hull.

So I decided to use some thicker sections of sprue to make two upright pillars, and then insert these into the hull structure. Resting on the bottom and supporting the top, they should act as braces when I insert the turret. I'm going to exercise patience and caution and give these a good few hours to cement in place strongly before I retry turret insertion!

A second sitting today has brought me to the stage of completion, construction wise. Thankfully there were no more debacles like the above episode with the running gear! I did find that quite a few holes for the more delicate parts needed opening up a little, so as not to break some of the nice little tools attached to the hull.

For once I exercised due caution, and waited till the paint had properly dried before assembling the hull!

One of the only ugly bits of flash on this overall very clean model was this bi on the barrel.

Cleaned and ready for assembly...

Presto!

Nearly there: adding last few bits to the hull,

prior to mounting the turret.

One final bit of ad-libbing seemed necessary to me when I tried unsuccessfully to fit the turret: the downward pressure caused by pressing the turret into place made the upper surface of the Tiger I sag and bow, so much so the turret wouldn't clip into place and turn. Whittling the small nubs on the underside of the turret to widen the gap there didn't seem to help either.

Sprue pillar upper-hull support one in place.

So I decided to use some thicker sections of sprue to make two upright pillars, and then insert these into the hull structure. Resting on the bottom and supporting the top, they should act as braces when I insert the turret. I'm going to exercise patience and caution and give these a good few hours to cement in place strongly before I retry turret insertion!

Sprue pillar upper-hull support two in place.

The near complete Tiger I sits amidst the various tools I'm using,

as I once again manage to remain patient enough to let the glue set.

Kaboom! The Tiger puts its head on, the pillars work a treat.

Pre painting thoughts. Well, aside from my own errors, this is another nice kit. There were one or two slight niggles, such as holes and pegs where the fit was a bit too tight for the delicate parts involved (esp. with some of the hull stowage, such as the nicely detailed and fully sculpted in-the-round tools), and the difficulty of mounting the turret. But all things considered it's a fun kit to build, and looks great to my eyes.

* Not a typo, that's how he spells his name, Slovak style!

Nice outcome, and great tips on what to look out for during the build. Just about to construct (is that the right word on a snap kit:) one of these bad boys as a 'palate cleanser' after building the Revell 1/72 Tiger 1 Ausf E (which turned into the best kit/paint/weathering job I've ever done, well except for those link and length tracks....having not built armour before, maaaaan are they fiddly, plus I lost that beautifully turned machine gun to the carpet monster... thank god for brass tubing). The detail on this kit is almost up to the Revell standard by the look of it. Cool beans!

ReplyDeleteThanks for the positive feedback, and I'm glad you found this post helpful. I've just built my second Zvezda snap-fit kit, the 1/72 Ferdinand. The very cleverly designed tracks are a great feature of these kits. So much better than the ultra-fiddly link'n'length variety!

Delete